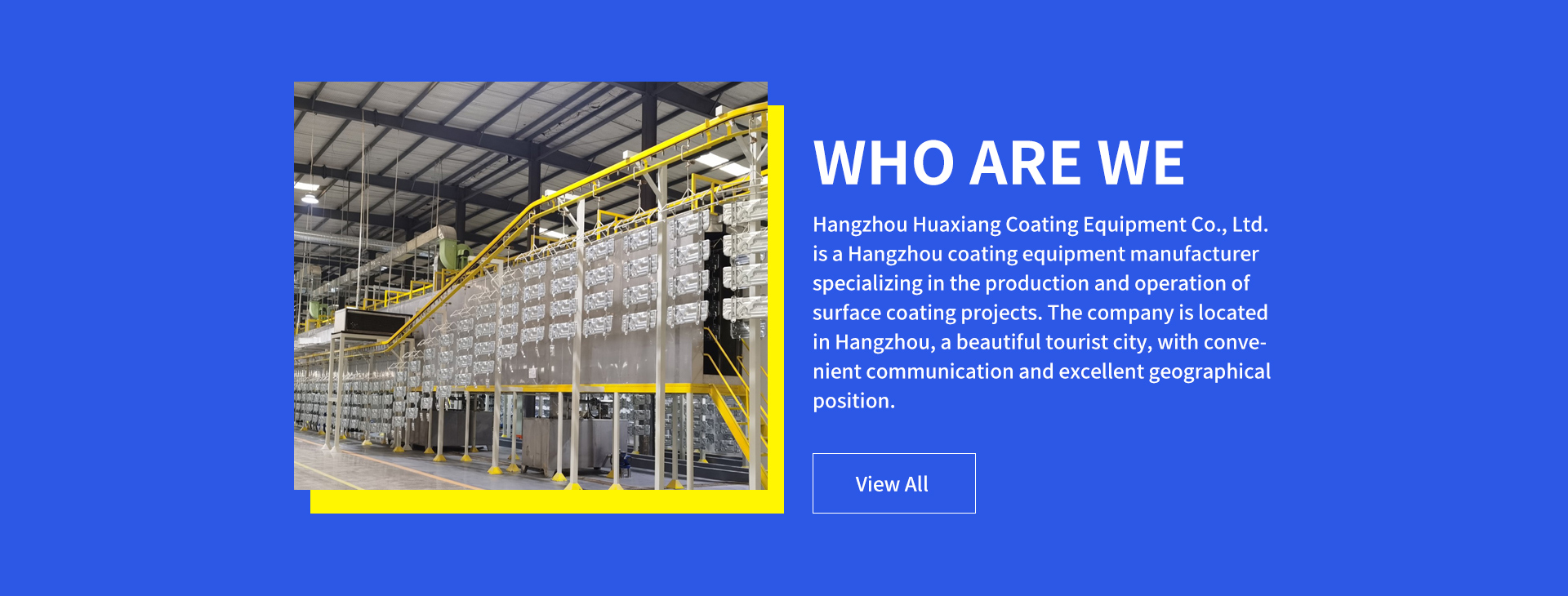

An Industrial Powder Coating Line is a high-performance system designed to apply durable, eco-friendly finishes to metal and composite surfaces across large-scale production environments. These fully automated lines integrate pretreatment, electrostatic spraying, curing, and recycling stages, minimizing manual labor while maximizing throughput. Industrial powder coating lines are renowned for their precision, energy efficiency, and compliance with strict environmental regulations, as they eliminate solvents and reduce VOC emissions. Ideal for automotive, aerospace, construction, and appliance industries, they deliver uniform coatings with exceptional corrosion resistance and aesthetic appeal. By optimizing material recovery and reducing waste, industrial powder coating lines lower operational costs and support sustainable manufacturing practices.

1. Industrial Powder Coating Line Components and Functionality

An Industrial Powder Coating Line comprises pretreatment stations (degreasing, phosphating), electrostatic spray booths, conveyor systems, curing ovens, and powder recovery units. Pretreatment ensures surfaces are contaminant-free for optimal adhesion. Robotic spray guns apply charged powder particles uniformly, while conveyor belts transport parts through each stage. Curing ovens use infrared or convection heating to cure coatings at 160°C–220°C. Advanced recovery systems reclaim 95%+ overspray, and PLC controls enable real-time monitoring and adjustments for consistent quality.

2. Key Applications of Industrial Powder Coating Lines

Automotive factories use Industrial Powder Coating Lines for vehicle frames, wheels, and engine components. Construction companies coat structural steel, bridges, and architectural panels for weather resistance. Appliance manufacturers apply scratch-proof finishes to refrigerators, washing machines, and HVAC systems. The aerospace sector relies on these lines for lightweight, heat-resistant coatings, while furniture makers achieve high-gloss or textured finishes. Their scalability makes them suitable for both mass production and custom batches.

3. Design Considerations for Industrial Powder Coating Lines

Efficient design prioritizes space optimization, energy savings, and operator safety. Compact layouts reduce floor space without compromising workflow. Heat recovery systems in ovens cut energy consumption by 30%, while explosion-proof electrical systems and HEPA filters mitigate fire and health risks. Modular designs allow integration with IoT sensors for predictive maintenance and process automation. Compliance with ISO 14001 (environmental management) and OSHA safety standards is critical for industrial powder coating lines.

4. Selecting the Best Industrial Powder Coating Line

Evaluate systems based on production volume, part dimensions, and coating specifications. High-throughput operations require multi-zone ovens, robotic arms, and automated powder recovery. For smaller facilities, semi-automatic lines with manual spray booths may suffice. Verify supplier certifications (CE, ISO 9001), energy efficiency ratings, and after-sales support. Prioritize systems with ≥95% powder recovery rates and compatibility with diverse coating materials (epoxy, polyester).

5. Q&A on Industrial Powder Coating Line Equipment

Q: How do industrial powder coating lines enhance production efficiency?

A: Automation reduces cycle times and ensures consistent coating thickness.

Q: What safety features are vital for industrial powder coating lines?

A: Explosion-proof lighting, grounded equipment, and fire suppression systems.

Q: Can these lines handle heavy or oversized parts?

A: Customizable conveyors and adjustable spray booths accommodate large components.

Q: How do industrial powder coating lines support sustainability?

A: Closed-loop recycling reduces waste, while low-VOC powders meet EPA standards.

Q: What maintenance ensures longevity of the system?

A: Regular filter cleaning, nozzle inspections, and oven temperature calibration.

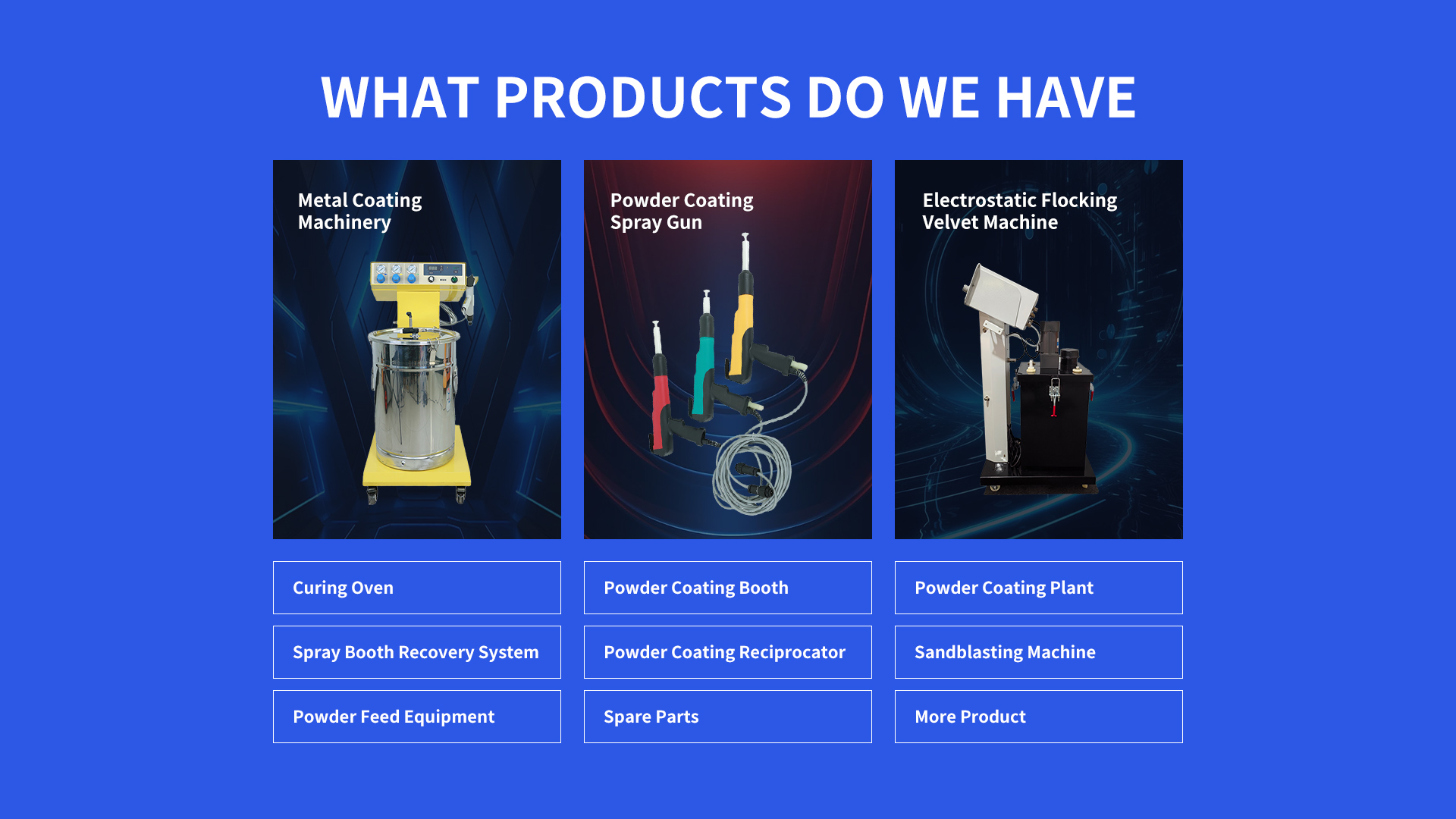

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com